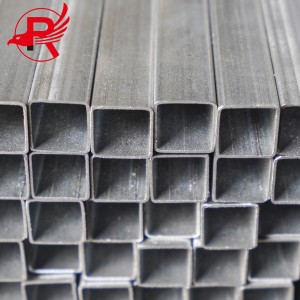

បំពង់ដែកស័ង្កសីរាងការ៉េច្រើនទំហំ

បំពង់ការ៉េស័ង្កសីគឺជាប្រភេទបំពង់ដែកប្រហោងរាងការ៉េដែលមានរាង និងទំហំផ្នែកការ៉េ ដែលធ្វើពីដែកស័ង្កសីរមូរក្តៅ ឬរមូរត្រជាក់ ឬខ្សែរបុំស័ង្កសីជាបំពង់ទទេតាមរយៈដំណើរការពត់ត្រជាក់ ហើយបន្ទាប់មកតាមរយៈការផ្សារប្រេកង់ខ្ពស់ ឬបំពង់ដែកប្រហោងដែលបង្កើតត្រជាក់ដែលផលិតជាមុន ហើយបន្ទាប់មកតាមរយៈបំពង់ការ៉េស័ង្កសីជ្រលក់ក្តៅ។

បំពង់ការ៉េស័ង្កសីត្រូវបានគេប្រើប្រាស់ជាទូទៅក្នុងការសាងសង់ វិស្វកម្ម និងកម្មវិធីឧស្សាហកម្ម ដោយសារតែភាពធន់ និងភាពធន់នឹងការច្រេះរបស់វា។ ខាងក្រោមនេះគឺជាព័ត៌មានលម្អិតធម្មតាមួយចំនួននៃបំពង់ការ៉េស័ង្កសី៖

សម្ភារៈ៖ បំពង់ដែករាងការ៉េស័ង្កសីជាធម្មតាត្រូវបានផលិតពីដែកថែប និងស្រោបដោយស្រទាប់ស័ង្កសីដើម្បីការពារការច្រេះ។

ទំហំ៖ ទំហំនៃបំពង់ដែកស័ង្កសីការ៉េមានភាពខុសប្លែកគ្នាយ៉ាងខ្លាំង ប៉ុន្តែទំហំទូទៅគឺ 1/2 អ៊ីញ, 3/4 អ៊ីញ, 1 អ៊ីញ, 1-1/4 អ៊ីញ, 1-1/2 អ៊ីញ, 2 អ៊ីញជាដើម។ កម្រាស់ជញ្ជាំងផ្សេងៗគ្នា។

ការព្យាបាលលើផ្ទៃ៖ ថ្នាំកូតស័ង្កសីផ្តល់ឱ្យបំពង់ការ៉េនូវរូបរាងប្រាក់ភ្លឺចែងចាំង និងផ្តល់ស្រទាប់ការពារប្រឆាំងនឹងច្រែះ និងការច្រេះ។

កម្លាំង និងសមត្ថភាពទ្រទម្ងន់៖ បំពង់ការ៉េស័ង្កសីត្រូវបានគេស្គាល់ដោយសារកម្លាំងខ្ពស់ និងសមត្ថភាពទ្រទម្ងន់ ដែលធ្វើឱ្យវាសមស្របសម្រាប់កម្មវិធីរចនាសម្ព័ន្ធដូចជាធ្នឹមទ្រ ស៊ុម និងសសរ។

ការផ្សារ និងការផលិត៖ បំពង់ការ៉េស័ង្កសីអាចត្រូវបានផ្សារ និងផលិតយ៉ាងងាយស្រួល ដើម្បីបង្កើតរចនាសម្ព័ន្ធ និងសមាសធាតុផ្ទាល់ខ្លួន។

កម្មវិធី: បំពង់ការ៉េស័ង្កសីត្រូវបានគេប្រើជាទូទៅនៅក្នុងការសាងសង់ របង រនាំងដៃ គ្រឿងសង្ហារឹមក្រៅផ្ទះ និងកម្មវិធីឧស្សាហកម្មផ្សេងៗ។

១. ភាពធន់នឹងការច្រេះ៖ ការលាបស័ង្កសីគឺជាវិធីសាស្ត្រការពារការច្រេះដែលមានប្រសិទ្ធភាព និងសន្សំសំចៃ ដែលត្រូវបានគេប្រើប្រាស់ជាញឹកញាប់។ ប្រហែលពាក់កណ្តាលនៃទិន្នផលស័ង្កសីរបស់ពិភពលោកត្រូវបានប្រើប្រាស់ក្នុងដំណើរការនេះ។ ស័ង្កសីមិនត្រឹមតែបង្កើតជាស្រទាប់ការពារក្រាស់នៅលើផ្ទៃដែកប៉ុណ្ណោះទេ ប៉ុន្តែវាក៏មានប្រសិទ្ធភាពការពារកាតូតផងដែរ។ នៅពេលដែលថ្នាំកូតស័ង្កសីត្រូវបានខូចខាត វានៅតែអាចការពារការច្រេះនៃសម្ភារៈមូលដ្ឋានដែកដោយការការពារកាតូត។

2. ដំណើរការពត់ត្រជាក់ និងផ្សារល្អ៖ ភាគច្រើនប្រើថ្នាក់ដែកកាបូនទាប តម្រូវការមានដំណើរការពត់ត្រជាក់ និងផ្សារល្អ ក៏ដូចជាដំណើរការបោះត្រាជាក់លាក់មួយ។

៣. ការឆ្លុះបញ្ចាំង៖ វាមានការឆ្លុះបញ្ចាំងខ្ពស់ ដែលធ្វើឱ្យវាក្លាយជារបាំងប្រឆាំងនឹងកំដៅ

៤. ភាពរឹងមាំនៃថ្នាំកូតគឺខ្លាំង ស្រទាប់ស័ង្កសីបង្កើតជារចនាសម្ព័ន្ធលោហធាតុពិសេស រចនាសម្ព័ន្ធនេះអាចទប់ទល់នឹងការខូចខាតមេកានិចក្នុងការដឹកជញ្ជូន និងការប្រើប្រាស់។

៥. ការព្យាបាលលើផ្ទៃ៖ ថ្នាំកូតស័ង្កសីផ្តល់ឱ្យបំពង់ការ៉េនូវរូបរាងប្រាក់ភ្លឺចែងចាំង និងផ្តល់ស្រទាប់ការពារប្រឆាំងនឹងច្រែះ និងការច្រេះ។

៦. កម្លាំង និងសមត្ថភាពទ្រទម្ងន់៖បំពង់ដែកស័ង្កសីរាងការ៉េធំត្រូវបានគេស្គាល់ដោយសារកម្លាំងខ្ពស់ និងសមត្ថភាពទ្រទម្ងន់របស់វា ដែលធ្វើឱ្យវាសមស្របសម្រាប់កម្មវិធីរចនាសម្ព័ន្ធដូចជាធ្នឹមទ្រ ស៊ុម និងសសរ។

៧. ការផ្សារ និងការផលិត៖បំពង់ដែកស័ង្កសី Q235អាចត្រូវបានផ្សារ និងផលិតយ៉ាងងាយស្រួល ដើម្បីបង្កើតរចនាសម្ព័ន្ធ និងសមាសធាតុផ្ទាល់ខ្លួន។

កម្មវិធីនៃបំពង់ដែកស័ង្កសីគឺទូលំទូលាយណាស់ ដែលភាគច្រើនត្រូវបានប្រើនៅក្នុងវិស័យដូចខាងក្រោម៖

១. វិស័យសំណង់ និងសំណង់៖ បំពង់ដែកស័ង្កសីអាចត្រូវបានប្រើសម្រាប់រចនាសម្ព័ន្ធទ្រទ្រង់អគារ ប្រព័ន្ធបំពង់ក្នុងផ្ទះ និងក្រៅផ្ទះ ជណ្តើរ និងរនាំងដៃ និងគោលបំណងរចនាសម្ព័ន្ធស្ថាបត្យកម្មផ្សេងទៀត។

២. វិស័យដឹកជញ្ជូន៖ បំពង់ដែកស័ង្កសីអាចត្រូវបានប្រើដើម្បីផលិតគ្រឿងបន្លាស់នៃយានយន្តដឹកជញ្ជូន ដូចជាបំពង់ផ្សែងរថយន្ត ស៊ុមម៉ូតូជាដើម។

៣. ក្នុងវិស័យវិស្វកម្មថាមពល៖ បំពង់ដែកស័ង្កសីអាចត្រូវបានប្រើសម្រាប់ទ្រទ្រង់ខ្សែ បំពង់ខ្សែ ទូត្រួតពិនិត្យ និងផ្សេងៗទៀតក្នុងវិស្វកម្មថាមពល។

៤. វិស័យរុករកប្រេង និងឧស្ម័ន៖ បំពង់ដែកស័ង្កសីអាចត្រូវបានប្រើនៅក្នុងប្រព័ន្ធបំពង់បង្ហូរប្រេង រចនាសម្ព័ន្ធអណ្តូង និងការផ្ទុកឧស្ម័នក្នុងការរុករកប្រេង និងឧស្ម័ន។

៥. វាលកសិកម្ម៖ បំពង់ដែកស័ង្កសីអាចត្រូវបានប្រើសម្រាប់ប្រព័ន្ធធារាសាស្រ្តវាលកសិកម្ម ការគាំទ្រសួនច្បារជាដើម។

| ស្តង់ដារ | JIS G3302 1998, ASTM A653M/A924M 2004, ទាំងអស់ស្របតាមសំណើរបស់អតិថិជន |

| កម្រាស់ | ពី 0.12mm ដល់ 4.0mm ទាំងអស់អាចរកបាន |

| ទទឹង | ពី 600mm ដល់ 1250mm មានទាំងអស់ |

| ទម្ងន់ | ពី 2-10 ម៉ែត្រគូប តាមការស្នើសុំរបស់អតិថិជន |

| ទម្ងន់ថ្នាំកូតស័ង្កសី | ៤០ក្រាម/ម៉ែត្រការ៉េ-២៧៥ក្រាម/ម៉ែត្រការ៉េ, សងខាង |

| ស្ពង់ហ្គល | ស្ពែងហ្គលធំ ស្ពែងហ្គលធម្មតា ស្ពែងហ្គលតូច មិនមែនស្ពែងហ្គល |

| ការព្យាបាលលើផ្ទៃ | ការព្យាបាលលើផ្ទៃ |

| គែម | គែមរោងម៉ាស៊ីនកិន, គែមកាត់ |

| អប្បបរមា | ការបញ្ជាទិញសាកល្បងអប្បបរមា 10 តោនសម្រាប់កម្រាស់នីមួយៗ 1x20' ក្នុងមួយការដឹកជញ្ជូន |

| ការបញ្ចប់ផ្ទៃ | លំនាំ | ពាក្យសុំ |

| ស្ពង់ហ្គលធម្មតា | ស្ព្រីងស្តង់ដារជាមួយលំនាំផ្កា | ការប្រើប្រាស់ទូទៅ |

| កាត់បន្ថយ spangles ជាងធម្មតា | កាត់បន្ថយ spangles ជាងធម្មតា | កម្មវិធីគំនូរទូទៅ |

| មិនមានភាពរលោង | ស្ព្រាងតូចៗដែលត្រូវបានបង្រួមអប្បបរមាខ្លាំងបំផុត | កម្មវិធីលាបពណ៌ពិសេស |

សំណួរ៖ តើ UA ជាក្រុមហ៊ុនផលិតមែនទេ?

ក: បាទ/ចាស៎ យើងជាក្រុមហ៊ុនផលិត។ យើងមានរោងចក្រផ្ទាល់ខ្លួនដែលមានទីតាំងនៅទីក្រុងធានជីន ប្រទេសចិន។

សំណួរ៖ តើខ្ញុំអាចមានការបញ្ជាទិញសាកល្បងត្រឹមតែប៉ុន្មានតោនប៉ុណ្ណោះបានទេ?

ក: ជាការពិតណាស់។ យើងអាចដឹកជញ្ជូនទំនិញជូនអ្នកជាមួយនឹងសេវាកម្ម LCL (បន្ទុកកុងតឺន័រតិចជាង)

សំណួរ៖ ប្រសិនបើគំរូឥតគិតថ្លៃ?

ក: គំរូឥតគិតថ្លៃ ប៉ុន្តែអ្នកទិញបង់ថ្លៃដឹកជញ្ជូន។

សំណួរ៖ តើអ្នកជាអ្នកផ្គត់ផ្គង់មាស ហើយធ្វើការធានាពាណិជ្ជកម្មដែរឬទេ?

ក: យើងផ្គត់ផ្គង់មាសរយៈពេលប្រាំពីរឆ្នាំ ហើយទទួលយកការធានាពាណិជ្ជកម្ម។